Nitro / Alcohol Series

SHAFT ROCKERS

Ultra Strong / Direct Replacement

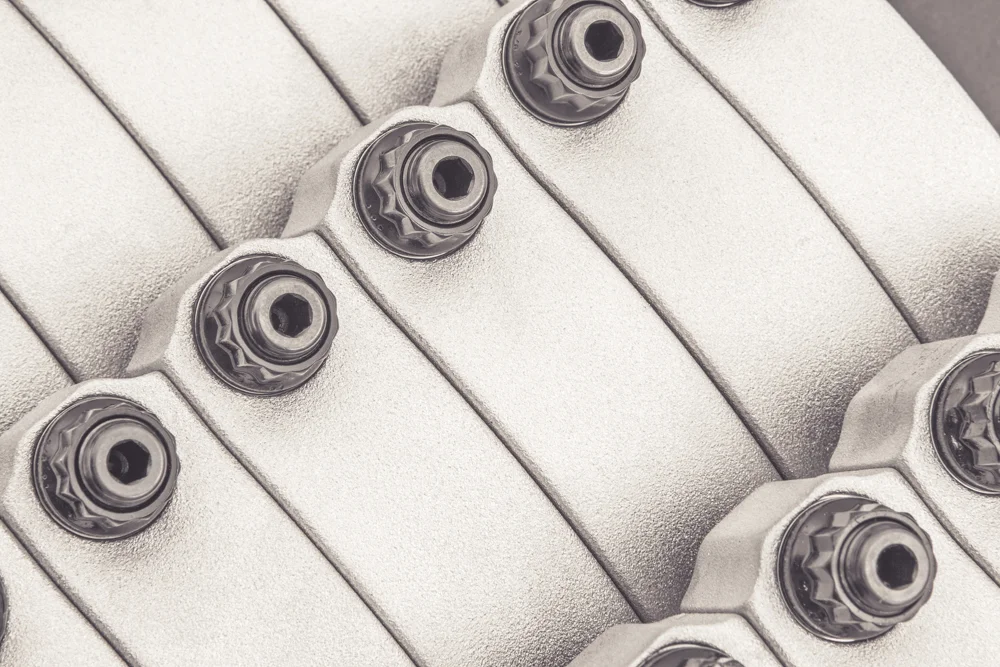

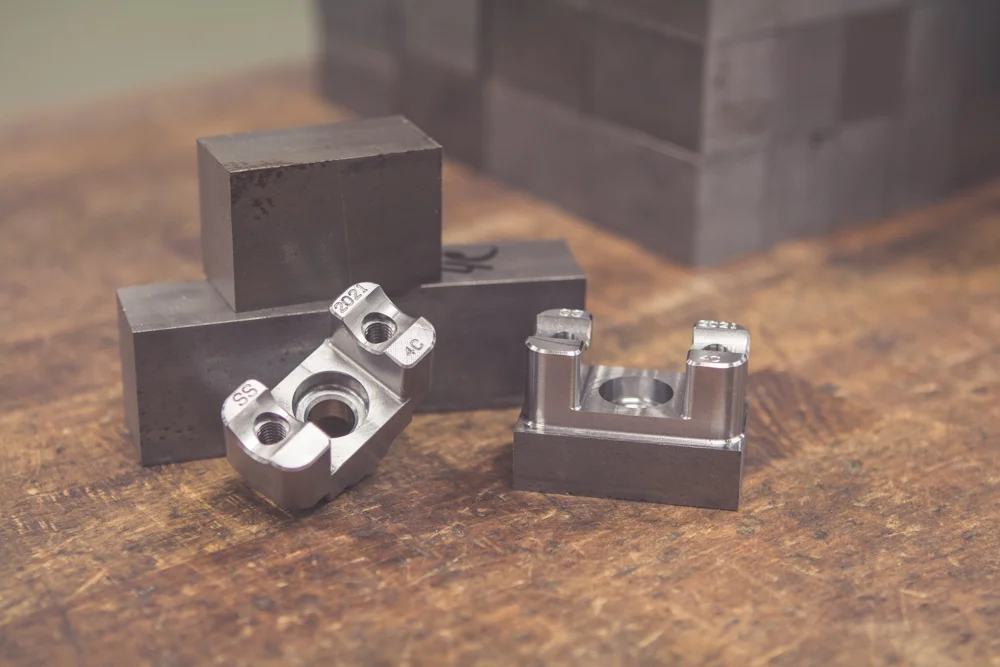

Proven through hundreds of wins and numerous championships, Jesel’s Pro Steel Top Fuel rockers have helped multiple drivers make it reliably to the final round. Manufactured from an annealed 4340 forging, these heat treated steel bodies have been designed using the latest FEA software to withstand deflection up to 10,000psi. Polish finished and coated to resist corrosion inherent with Nitro Methane, these rockers feature a precision honed Ampco 45 bushing which when mated to our DLC coated shaft results in an extremely low coefficient of friction. The rockers come standard with a .550” diameter tool steel nose roller and are machined to accept a 7/16-20 adjuster. The intake rockers are machined with an internal oil passage for direct shaft oiling. As with all Jesel rockers, various ratios are available as well as custom engineering services.

Series Benefits

Machined from Annealed 4340 Forgings

Precision honed bronze bushings

Accepts 7/16-20 lash adjusters

Multiple ratio choices

Fully re-buildable

Applications

AJPE / Top Fuel Head

BAE / Top Fuel Head

BAE / Alcohol Head

Top Fuel Shafts

These direct replacement Top Fuel Shafts are manufactured from through hardened H-13 tool steel with a stout .280” wall thickness. They are then processed with REM/ISF® Superfinish and DLC coated for improved wear and reduced friction.

Top Fuel Adjusters

Jesel offers a 7/16-20 and 12mm lash adjuster for use with the Nitro / Alcohol series rockers. These tool steel adjusters are through hardened and feature a .375” diameter nitrided ball end. The adjuster for the intake rocker features an internal oil circuit to direct oil the pushrod cup. The adjusters for the exhaust rocker are available with or without through hole oiling.

Our Rocker Story

When Chevrolet introduced its small-block V8 in 1955 one of its highly praised features was its lightweight stamped steel rocker system. With little more than a factory Duntov solid lifter cam a 7,000rpm redline was realistic. This economic valvetrain had its limits though. As long as mild seat pressures of around 100 pounds were used with low-lift hydraulic or flat tappet cams, life was good. As aftermarket cam manufacturers started grinding higher lifts, the rocker’s shortcomings began showing up. First, the rockers bottomed-out on the rocker studs because the slots were too short, then as spring pressures increased the studs pulled or broke out of the head bosses. The fixes came both from the aftermarket and GM.