Sportsman Steel Series

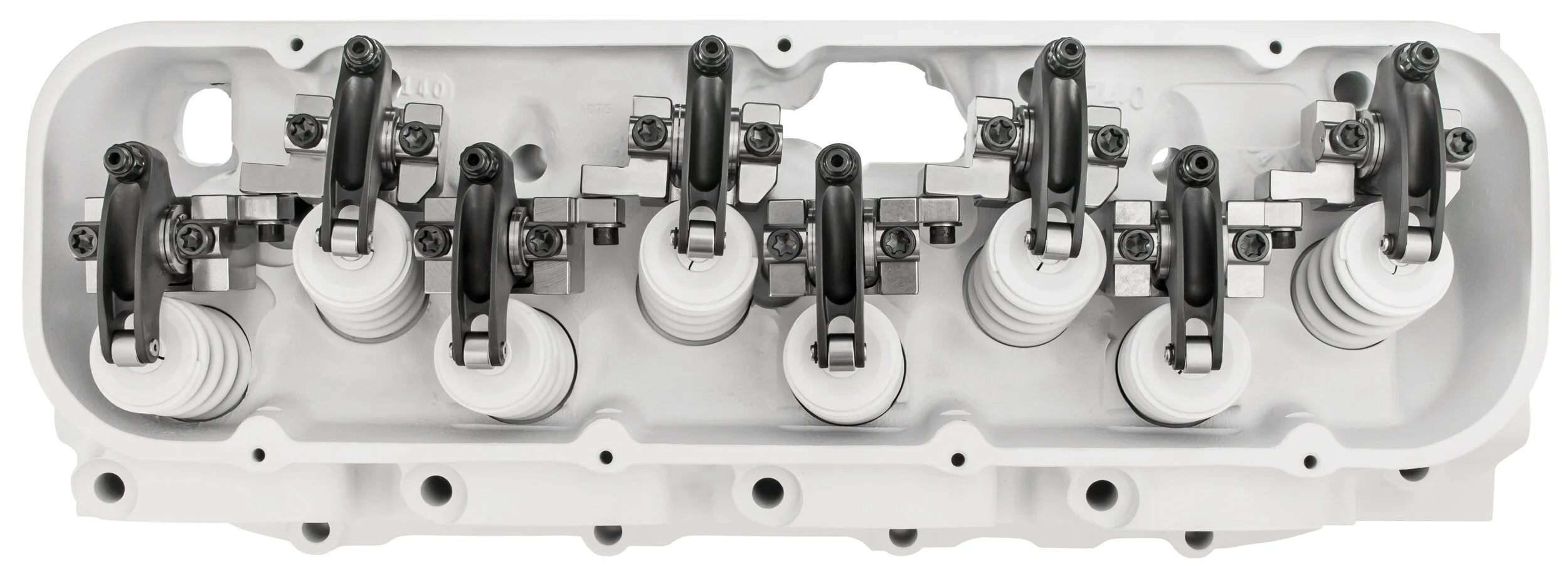

SHAFT ROCKERS

Affordable. Replacement. Steel.

Jesel Engineers have combined all of the features of our Pro Aluminum Rockers with the durability of our Pro Steel Rockers. Jesel Sportsman Steel Rockers provide engine builders with the option of high strength steel rockers at an extremely affordable price and can be ordered separately or as an upgrade to certain Pro Aluminum rocker systems.

The Jesel Sportsman Steel Rockers are assembled with all of the proven components of our Pro Aluminum rockers. Featuring a .625" wide body with an ultralight slot to reduce weight and moment of inertia. They’re designed to be a direct replacement for the current Pro Aluminum bodies and will bolt to existing stands. Featuring a .360" wide non-needle valve tip roller and cup style tool steel adjuster, the rockers can be optioned with needle bearing nose rollers and ball style lash adjusters for high lift / high spring pressure applications. The rocker geometry is designed to minimize roller movement on the valve tip and each rocker body is manufactured from premium alloy steel. A through hardened heat treating process along with a black oxide coating will provide for years of dependable service and corrosion resistance.

Ideal for turbocharged, supercharged, nitrous, endurance and marine engine types.

Available Applications

AFR Magnum BBC

AFR Renegade SBF

All Pro 11° SBC

All Pro 13° SBC

All Pro LS3/LS7 Retro

All Pro LSW 12-1

Brodix 11x / ASCS

Brodix 15° SBF

Brodix 24° BBC

Brodix GB2000

Brodix SR20

Brodix Track 1 SBF

Chevy 23° SB

Chrysler W7

Dart Pro 1 / Pro 2

Dart Pro 1-20

Edelbrock Glidden SC1

Edelbrock LS-R

Ford D3 Ninja

GM / Dart LS3

GM LS 1

GM LS 7

GM SB 2.2

Mast LS3/LS7

TFS Gen X LS3

TFS High Port SBF

Ultra Pro 707 CT

MRH 18° BBC

TFS A460 BBF

TFS Gen X LS1

Sportsman Steel Features

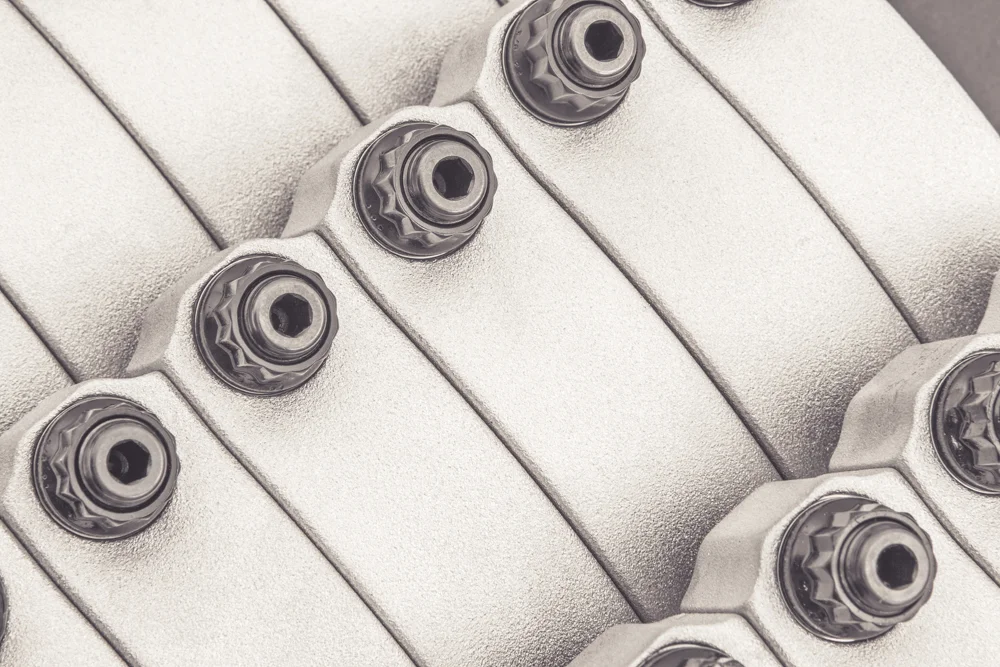

Shaft Needle Bearings

Full compliment needle bearing assembly operates with minimal lubrication while distributing load evenly over shaft surface.

Clip-Pin Nose Roller

Securely retained .520” diameter Tool Steel Nose Roller operates with less friction and decreased valve guide wear.

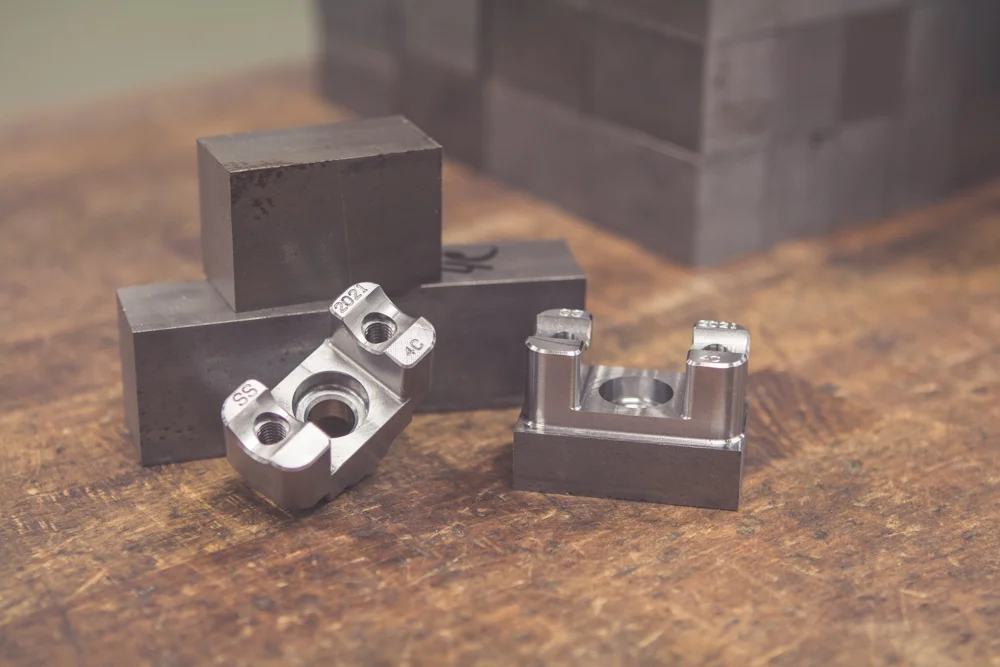

Tool Steel Lash Adjusters

CNC machined, heat treated alloy steel lash adjusters have been proven through years of abuse.

Centerless Ground Shafts

Precision ground and heat treated Tool Steel shaft provides years of durable service.

Optional Ball Adjuster

Has less friction than cup type adjusters. Makes rocker arm stronger by increasing the adjuster thread area and eliminates counterbore area.

Optional Needle Roller

Recommended for use with high lift, high spring pressure applications. Prevents the roller from stalling and skidding across the valve tip. Highly recommended when using .312” or smaller valve stems.

Our Rocker Story

When Chevrolet introduced its small-block V8 in 1955 one of its highly praised features was its lightweight stamped steel rocker system. With little more than a factory Duntov solid lifter cam a 7,000rpm redline was realistic. This economic valvetrain had its limits though. As long as mild seat pressures of around 100 pounds were used with low-lift hydraulic or flat tappet cams, life was good. As aftermarket cam manufacturers started grinding higher lifts, the rocker’s shortcomings began showing up. First, the rockers bottomed-out on the rocker studs because the slots were too short, then as spring pressures increased the studs pulled or broke out of the head bosses. The fixes came both from the aftermarket and GM.