Pro Steel

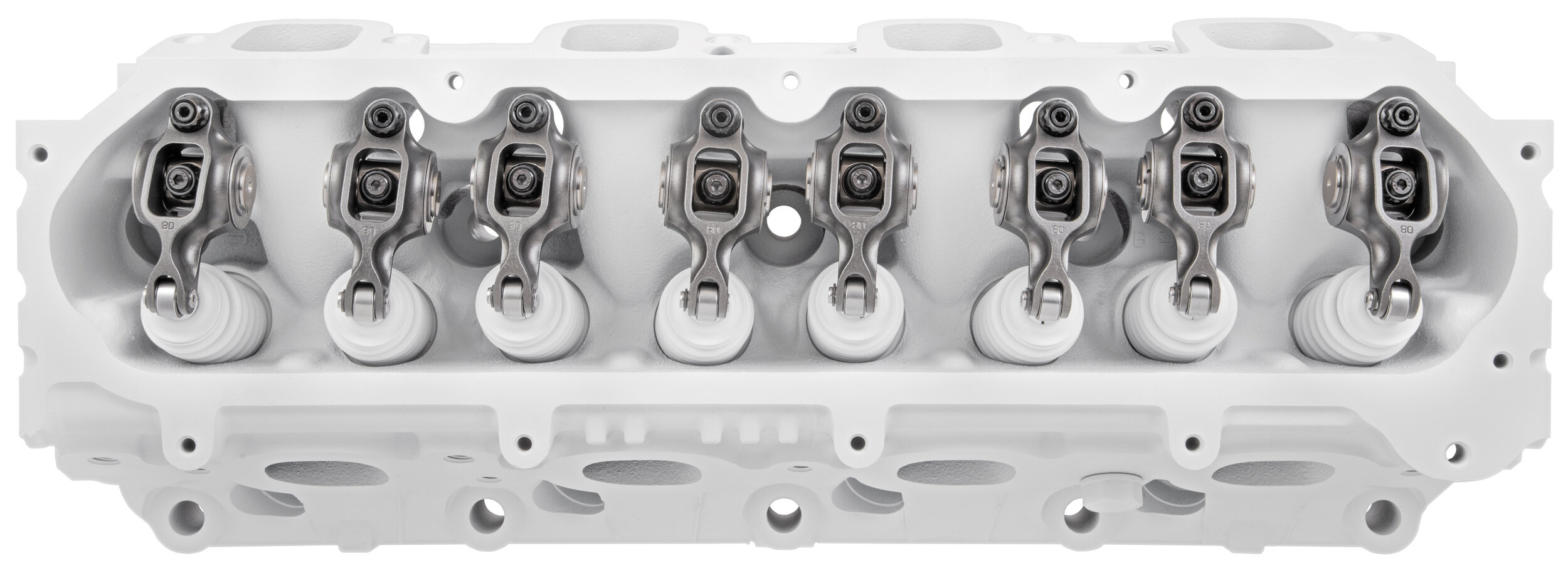

PEDESTAL ROCKERS

Designed for racers running the GM LS7 and Gen 5 LT heads where class rules don’t allow for head modifications, the Jesel Pro Steel Pedestal Rocker is the perfect solution for your valvetrain needs. Machined to the highest standards and engineered to be lightweight yet strong, we're confident our Pro Steel Pedestal Rockers can handle whatever you throw at them.

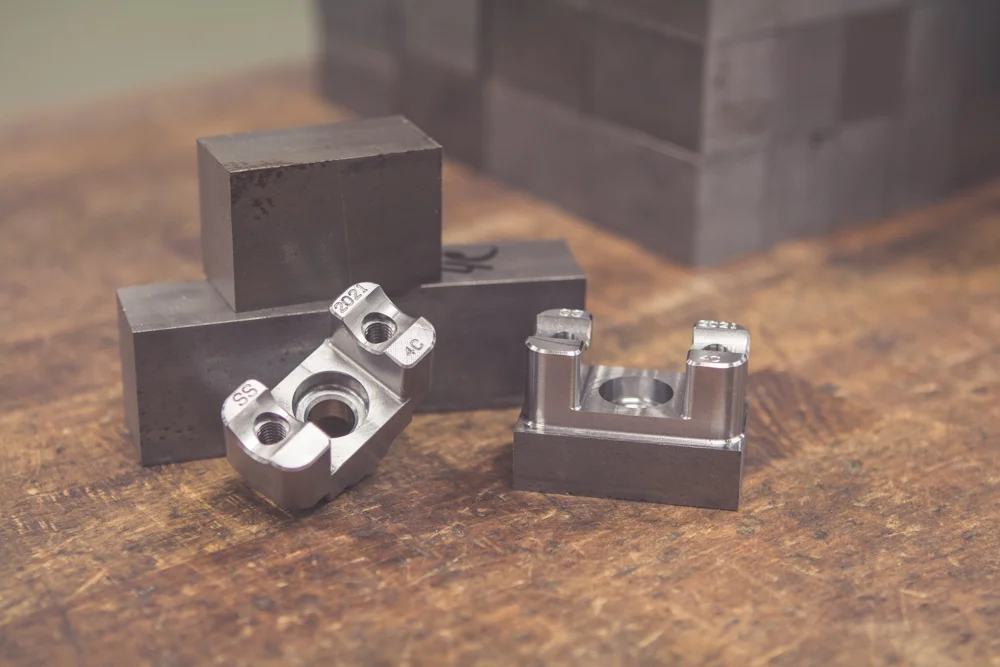

Jesel Pedestal Pro Steel Rockers are machined from heat treated 4340 billet steel which is surface coated to resist rust and corrosion. The rockers rotate on a precision ground tool steel trunnion fitted with dual 3/8” wide full compliment needle bearings with thrust washers for added high rpm stability. As with all of our high-end rockers, needle bearing valve tip rollers and ARP hardware are standard. These rockers are fitted with our tool steel ball end lash adjuster which must be used with cup end pushrods.

These jewelry-like Pedestal Rockers are designed for stock length valves and are available in either 1.80 or 1.90 ratios. They easily handle increased lift, spring pressure and RPM in naturally aspirated and turbo/nitrous engine builds.

Standard Features

Machined from 4340 billet steel

Designed for use with stock length valves

Can handle higher spring pressures and increased valve lift over stock

Available in 1.80 or 1.90 ratios

.250” wide x .520” diameter needle bearing nose roller

Threaded ball style lash adjuster

Heat treated tool steel trunnion rotates on dual .312” needle bearings

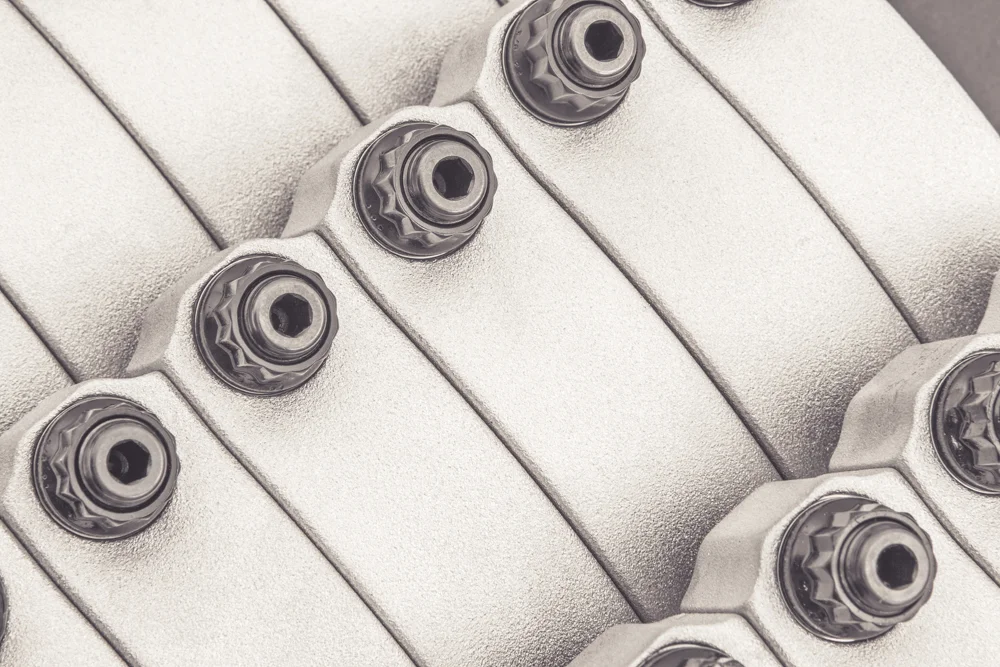

ARP mounting hardware

Our Rocker Story

When Chevrolet introduced its small-block V8 in 1955 one of its highly praised features was its lightweight stamped steel rocker system. With little more than a factory Duntov solid lifter cam a 7,000rpm redline was realistic. This economic valvetrain had its limits though. As long as mild seat pressures of around 100 pounds were used with low-lift hydraulic or flat tappet cams, life was good. As aftermarket cam manufacturers started grinding higher lifts, the rocker’s shortcomings began showing up. First, the rockers bottomed-out on the rocker studs because the slots were too short, then as spring pressures increased the studs pulled or broke out of the head bosses. The fixes came both from the aftermarket and GM.