Pro Tie Bar

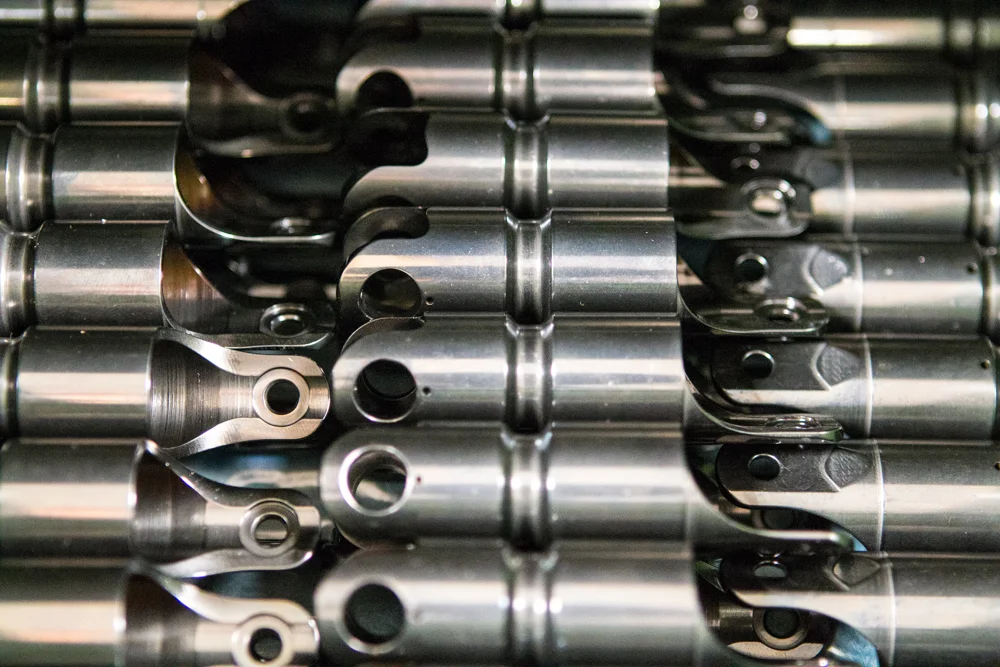

ROLLER LIFTERS

Built to go the distance.

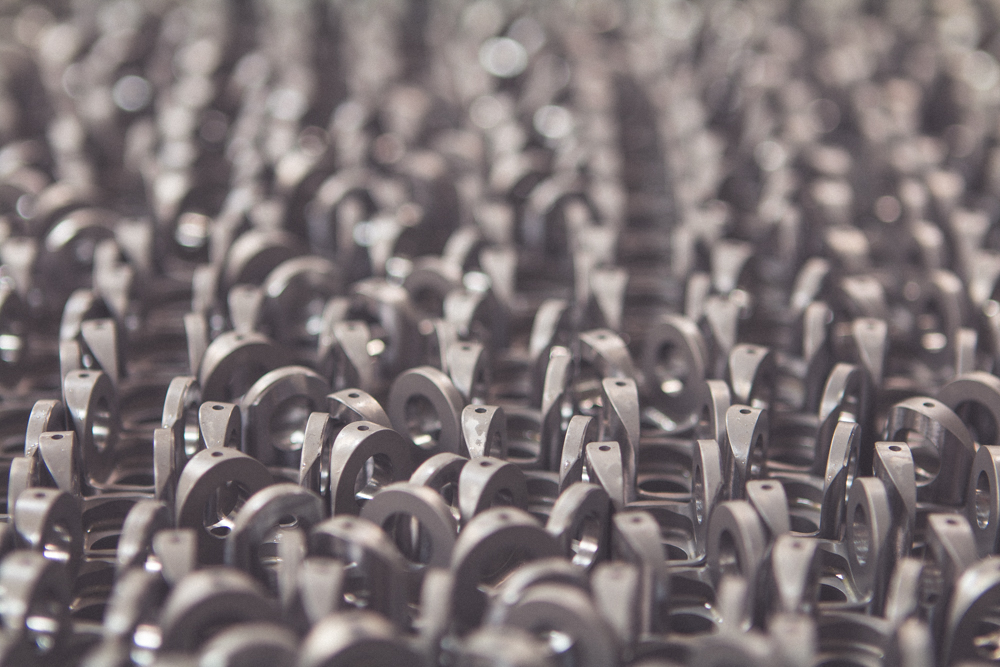

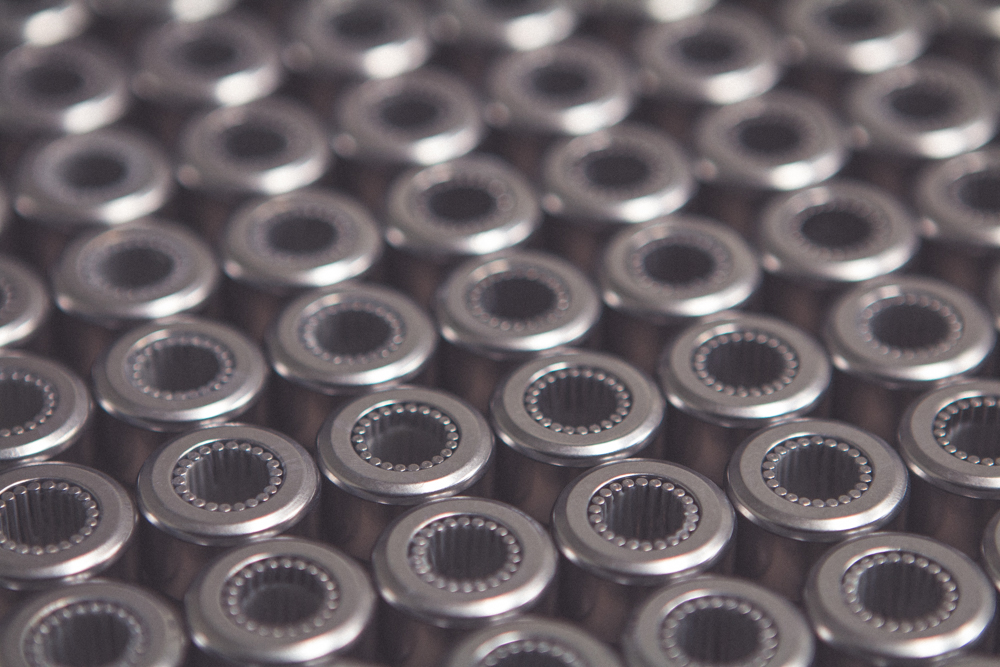

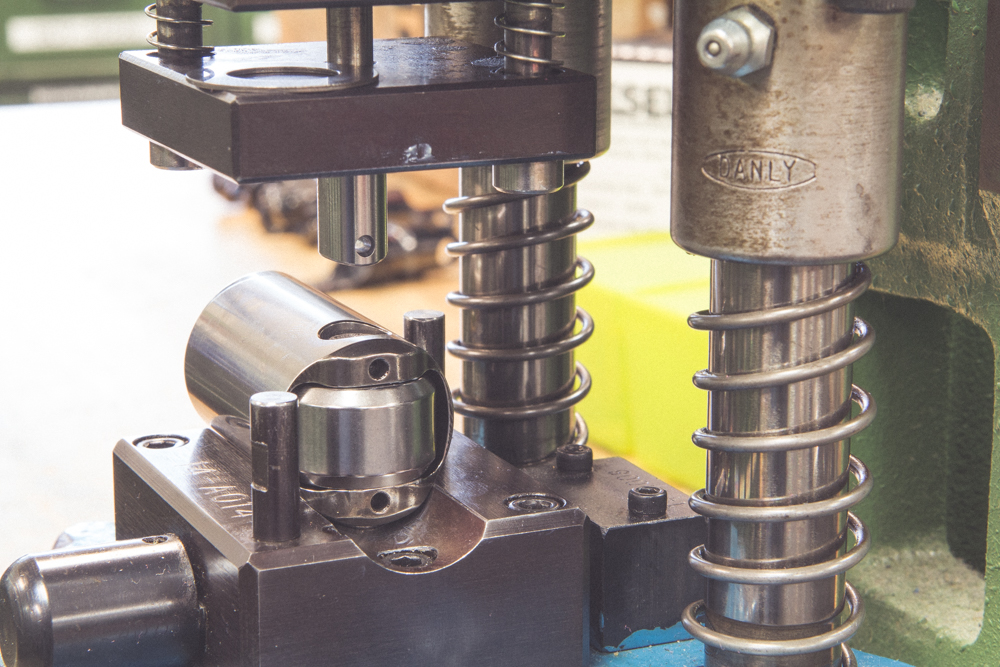

Introduced in 2009, this solid body, tie-bar design steel lifter is a perfect fit for sportsman and professional racers in every type of racing venue. Whether you are into drag, road, circle, or marine racing, this lifter was designed to be a cost effective alternative to our well proven Tie-Bar Series Lifters which have won numerous NHRA, NASCAR, SCCA and LeMans championships. To create these Solid Body Tie-Bar Lifters we use the same rollers, needles and axles found in our high end lifters, combined with a FEA designed ultra smooth REM/ISF® polished DLC coated, heat treated body, all held to tolerances far exceeding current industry standards. Lifter sets are now available in .842”, .875”, .905” and .937” diameters for all popular OEM and aftermarket racing engines.

Standard Features

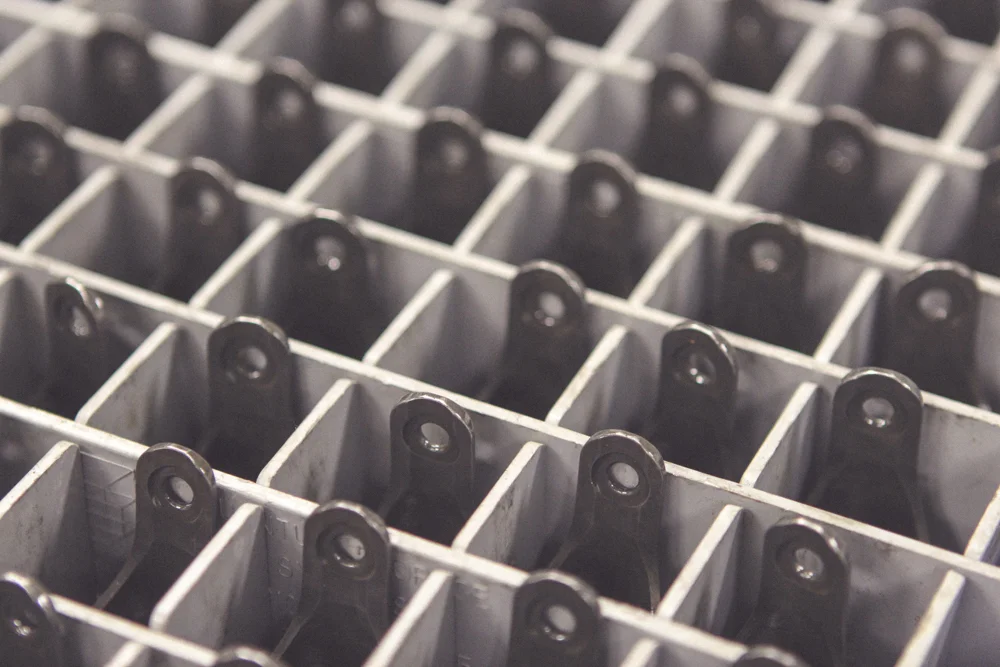

Heat treated stainless steel tie-bar secured with tool steel nuts

Precision sorted bearings feature pressure fed oiling

Precision ground REM polished heat treated body

Offset or centered pushrod seats

Heat treated tool steel roller

Oil flow should never be restricted to any Jesel Precision Roller Lifter.

Specifications

Offsets

Left Pair

Centered Pair

Right Pair

Splayed Pair

Bushed Lifters

We understand that you may have had bad experiences with needle roller lifters from other manufacturers, and may be more comfortable with bushed lifters going forward. Although we have always felt and continue to feel that a needle is the best option for a lifter, we now offer a bronze bushed roller option for customers that prefer them.

Now available for both Tie-Bar and Keyway Lifters, Jesel Bushed Lifters feature pressure fed oiling, and have been rigorously dyno tested and run through over one million cycles on our in-house Spintron.

Our Roller Lifter Story

Roller lifters had been around for years, being used in various applications such as radial aircraft engines, but when a few progressive engine builders started adapting them to race engines, horsepower and rpm made a huge leap forward. Cam grinders began designing cam profiles with shorter durations and higher rates of lift than a traditional solid lifter could tolerate. The result was incredible power gains especially with the typical modified O.E. style cylinder heads of the day. As valvetrain loads escalated with more lift, rocker ratio and spring pressure, the roller lifter was overtaxed and suffered frequent failures.