Pro Aluminum Series

Shaft Rocker Arms

Custom Built to Your Specifications

About Jesel Pro Aluminum Series Shaft Rockers

From NHRA Pro Stock to Sprint Cup, Jesel Pro Aluminum Series shaft rockers are the trusted choice for championship winning racers. Engine builders worldwide rely on Jesel rockers, acclaimed for setting the gold standard in high-performance valvetrain technology.

Superior Strength and Lightweight Design

Engineered with an exclusive custom blended 7000 Series aluminum alloy, Jesel Pro Aluminum Series shaft rockers offer exceptional durability without compromising weight. Tensile strength of our custom blended alloy at 300° far exceeds that of the less expensive, industry standard 2024 alloys. Low moment of inertia along with FEA designed bodies ensures that lobe lift is not wasted due to rocker body deflection.

Customizable for Optimal Performance

Jesel understands that precision customization is key to achieving peak performance. Our Pro Series shaft rocker systems can be tailored to meet specific racing requirements, including adjustments in rocker ratio, adjuster offset, and lightening options. Standard features such as a shotpeened surface finish, a profiled rocker tail, and a clipped-pin nose roller enhance durability and performance. Additionally, rocker stands can be custom ordered to suit engines with longer than stock valve lengths, ensuring a perfect fit for every race engine.

Elevate Your Race Engine with Jesel Pro Aluminum Series Shaft Rockers

Choose Jesel Pro Series shaft rockers to elevate your race engine's performance to championship levels. Explore the possibilities and customize your components to suit your racing needs, and step into the winner's circle with Jesel, the leader in valvetrain innovation.

Features & Options

-

Full complement needle bearing assembly operates with minimal lubrication while distributing load evenly over shaft surface.

-

Securely retained .520” diameter Tool Steel Nose Roller operates with less friction and decreased valve guide wear.

-

Precision ground and heat-treated Tool Steel shaft provides years of durable service.

-

Prolongs the rocker body service life by generating a compressive stress layer, which enhances resistance to fatigue.

-

Increases clearance for valve cover while also reducing the rocker’s moment of inertia.

-

CNC machined, heat treated H-13 tool steel lash adjusters feature a nitride process for wear protection.

-

Provides a stable and rigid mounting surface for shaft rocker assembly.

-

Fully rebuildable to Jesel factory specifications through the Jesel CPR department.

-

Rockers can be ordered in various ratios to suit your specific engine build. Some applications are ratio limited.

-

Has less friction than cup type adjusters. Makes rocker arm stronger by increasing the adjuster thread area and eliminates counter-bore area.

-

Manufactured from ARP 2000 material, these bolts can be torqued to 35 ft/lbs and are recommended for spring pressures exceeding 900 lbs. open.

-

Recommended for use with high lift, high spring pressure applications. Prevents the roller from stalling and skidding across the valve tip. Highly recommended when using .312” or smaller valve stems.

-

Rocker bodies tailored to your engine build. Choose from Standard Slot, lightweight Mohawk Beam or ultra-strong Solid Body.

-

Adjuster offset can be tailored to your specific engine build.

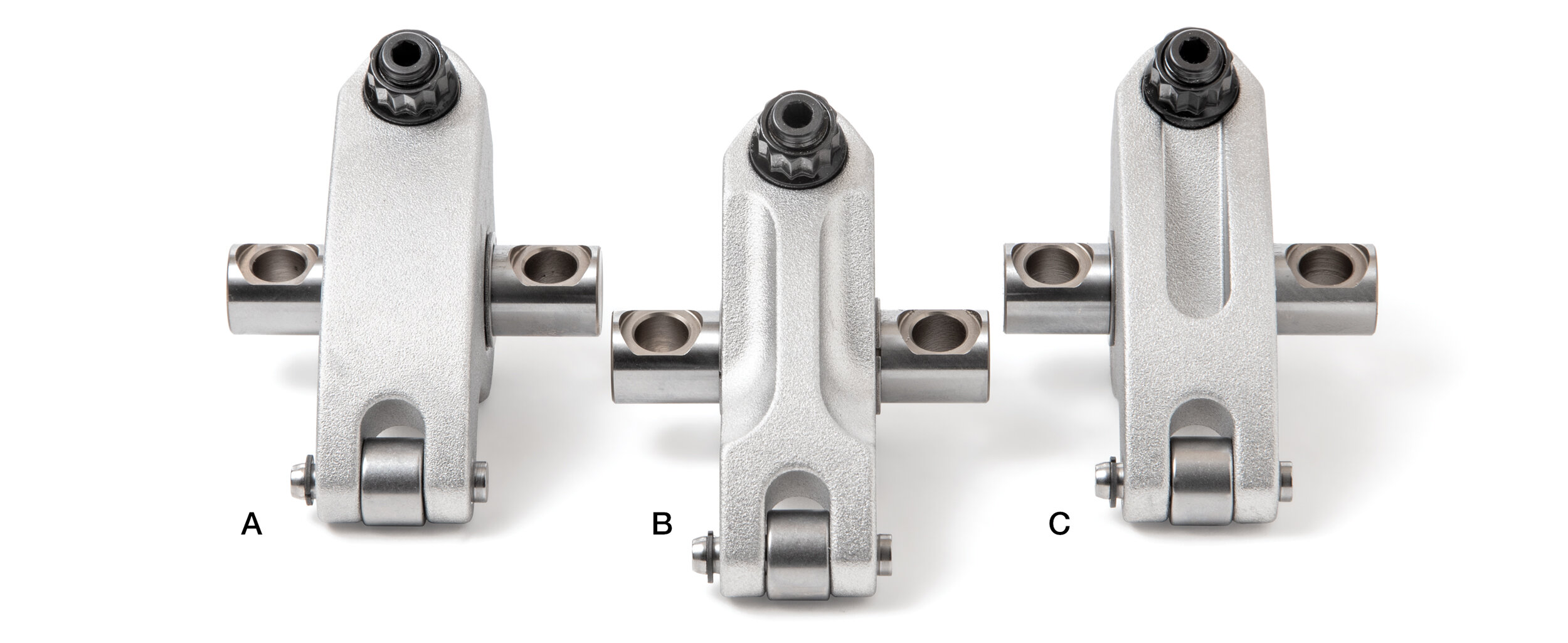

Available Rocker Bodies

A. Solid Body

1.650 Pivot BB Rocker / Weight: 210g

Our strongest rocker body. Intended for use with high cylinder pressure applications such as nitrous and blowers.

B. Mohawk Beam

1.650 Pivot BB Rocker / Weight: 195g

Our stiffest lightweight body. Lowest moment of inertia ideal for extremely high RPM valve control and extended spring life.

C. Standard Slot

1.650 Pivot BB Rocker / Weight: 202g

Our default lightening program. Provides for a stiff body capable of controlling the valvetrain at high RPM.

Tool Steel Ball & Cup Adjusters

All of Jesel’s lash adjusters are machined in house using high grade H-13 Tool Steel. They are then heat treated and finally put through a nitriding process to apply a hardened case on the parts for wear protection.

Optional Needle Rollers

Recommended for use with high lift, high spring pressure applications. Prevents the roller from stalling and skidding across the valve tip. Highly recommended when using .312” or smaller valve stems.

Our Rocker Story

When Chevrolet introduced its small-block V8 in 1955 one of its highly praised features was its lightweight stamped steel rocker system. With little more than a factory Duntov solid lifter cam a 7,000rpm redline was realistic. This economic valvetrain had its limits though. As long as mild seat pressures of around 100 pounds were used with low-lift hydraulic or flat tappet cams, life was good. As aftermarket cam manufacturers started grinding higher lifts, the rocker’s shortcomings began showing up. First, the rockers bottomed-out on the rocker studs because the slots were too short, then as spring pressures increased the studs pulled or broke out of the head bosses. The fixes came both from the aftermarket and GM.