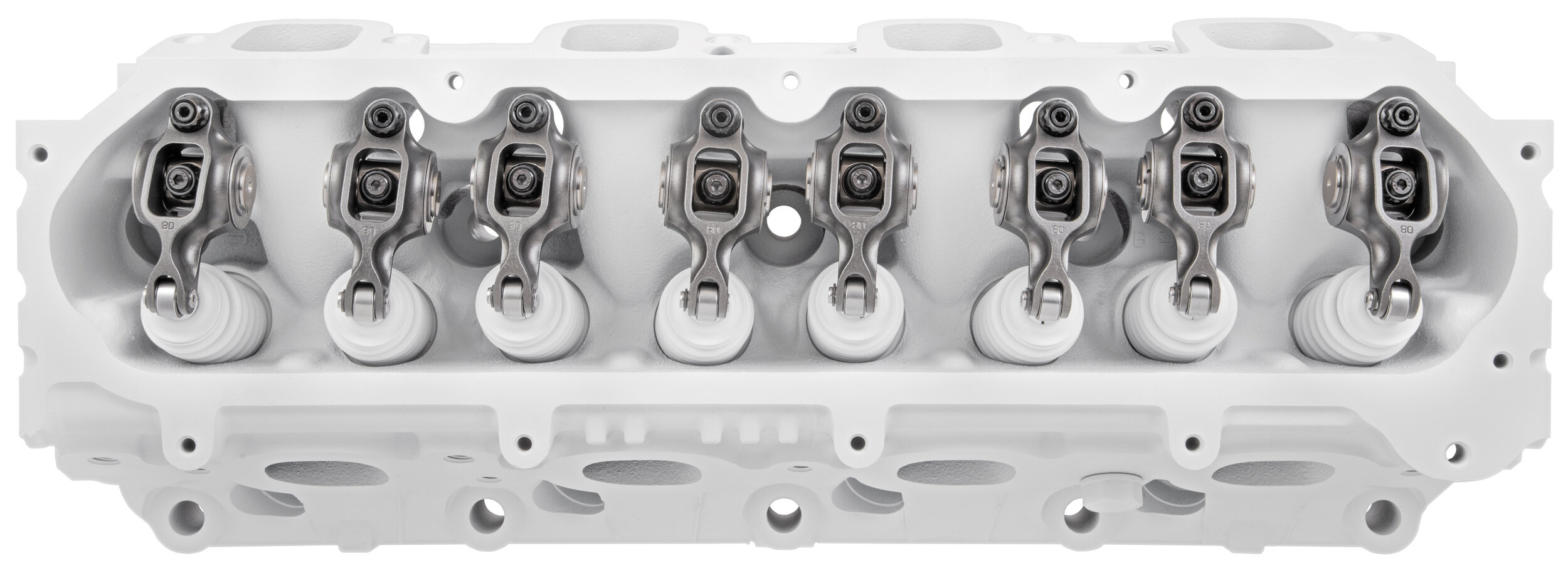

Pro Steel Series

Pedestal Rocker Arms

More spring pressure. More valve lift.

About Jesel Pro Steel Series Pedestal Rockers

For racers running GM LS7 and Gen 5 LT heads, as well as Dodge Gen 4/5 Viper and Ford Godzilla heads, where class rules restrict head modifications, Jesel Pro Steel Pedestal Rockers offer the ideal solution for superior valvetrain performance. Engineered to the highest standards, these rockers are both strong and lightweight, ensuring exceptional durability under the most demanding racing conditions.

Superior Material and Construction

Jesel Pro Steel Pedestal Rockers are crafted from heat treated 4140 billet steel, providing excellent strength and resilience. Each rocker is surface coated to resist rust and corrosion, ensuring long lasting reliability. The precision ground tool steel trunnion, fitted with dual 3/8” wide full complement needle bearings and thrust washers, offers enhanced high RPM stability, making these rockers perfect for high performance applications.

Advanced Features and Specifications

As with all of our high end rockers, these jewelry-like rockers are equipped with needle bearing valve tip rollers and ARP hardware as standard. The tool steel ball end lash adjuster, designed to be used with cup end pushrods, further enhances performance and reliability. Available in either 1.80 or 1.90 ratios, Jesel Pro Steel Pedestal Rockers are designed for stock length valves and can easily handle increased lift, spring pressure, and RPM in naturally aspirated and turbo/nitrous engine builds.

Features & Options

-

Full complement needle bearing assembly operates with minimal lubrication while distributing load evenly over shaft surface.

-

Precision ground and heat-treated Tool Steel shaft provides years of durable service.

-

Increases clearance for valve cover while also reducing the rocker’s moment of inertia.

-

CNC machined, heat treated H-13 tool steel lash adjusters feature a nitride process for wear protection.

-

.250” wide valve tip roller rotates on heavy-duty bearing steel needles to prevent the roller from stalling and skidding on the valve tip.

-

Bronze and/or hardened steel thrust washers are used to absorb heavy axial loads and prolong the life of the rocker shaft bearings.

-

Rocker kits include either ARP 2000 shaft bolts or ARP 8740 studs and nuts to secure the rockers to the mounting stands.

-

Manufactured from high-strength 4140 billet steel and engineered to handle increased spring pressures and valve lift over stock.

-

CNC machined, heat treated H-13 tool steel ball end lash adjusters feature a nitride process for wear protection.

-

Fully rebuildable to Jesel factory specifications through the Jesel CPR department.

-

Rockers can be ordered in various ratios to suit your specific engine build. Some applications are ratio limited.

Our Rocker Story

When Chevrolet introduced its small-block V8 in 1955 one of its highly praised features was its lightweight stamped steel rocker system. With little more than a factory Duntov solid lifter cam a 7,000rpm redline was realistic. This economic valvetrain had its limits though. As long as mild seat pressures of around 100 pounds were used with low-lift hydraulic or flat tappet cams, life was good. As aftermarket cam manufacturers started grinding higher lifts, the rocker’s shortcomings began showing up. First, the rockers bottomed-out on the rocker studs because the slots were too short, then as spring pressures increased the studs pulled or broke out of the head bosses. The fixes came both from the aftermarket and GM.